Dehumidify with Heat Exchangers

Industrial dehumidification, combined with heat recovery, leads to less energy consumption and a shorter return on the investment period. As a result, the system as a whole is more cost-effective and attractive to purchase.

Challenges and Solutions in Industrial Dehumidification

While commercial dehumidifiers play a significant role in regulating room temperature and controlling condensation in occupied spaces, industrial dehumidification systems are required for operational processes that necessitate specific humidity levels for efficient operation.

Particularly in industrial warehousing and food processing, operators often face a pressing need to control air humidity between spaces. The colder the climate, the more critical it is to control moisture. Traditional strip curtains and high-speed doors result in energy loss and create significant hurdles to transport.

However, energy consumption is a primary concern in the design of a dehumidification system. Most energy expended on dehumidification is used to remove moisture/water from the air.

Combining an industrial dehumidifier with a heat recovery unit is a perfect example of a win-win solution for solving the problems with humid air while significantly reducing energy consumption.

Some common challenges are:

- Moisture enters the cold store from outside through the open passage (natural heat transfer).

- Moisture is removed via the evaporators’ outlets. However, if the evaporators are not frequently defrosted, they lose their capacity to remove large amounts of moisture.

- Depending on the method, defrosting takes time and energy.

- Moisture entering the cold store can cause slippery floors, mold, corrosion, electrical malfunctions, and deterioration of product quality.

By implementing a heat recovery unit such as an air-to-air heat exchanger, heat from the regeneration process is recirculated and reused for the subsequent regeneration process of the dehumidifier. The heat transfer takes place without moisture transfer. As a result, heat is retained during the regeneration process of the dehumidifier, minimizing energy consumption for the industrial dehumidification process.

Besides ensuring that as much heat as possible is transferred from the exhaust air to the supply air (>80%), the heat exchanger should provide:

- Low maintenance requirements

- Long lifespan (>15 years)

- Limited pressure drop < 500 Pa (2″ WC)

- Corrosion resistance

- Fast return on investment

Heatex’s crossflow heat exchangers feature a lightweight construction, slim frames, and an optimized plate pattern, delivering superior efficiency while maintaining a low pressure drop.

Using our product selection software, Heatex Select enables accurate calculations of our products’ performance under different conditions.

Recommended Products for Industrial Dehumidification

Heatex Model H & H2

Heatex crossflow models H2 and H are made of aluminum heat transfer plates and Aluzinc end plates.

Additionally, we offer a wide range of configurations and options, such as:

- Epoxy-coated heat transfer plates

- Corrosion protected framework

- Plates distances between 1.6 – 12 mm (0.063″ – 0.47″), depending on the model)

- Sizes between 200 – 3000 mm (7.9″ – 118″), depending on model

- Max. differential pressure between 1800 – 3000 Pa ( 7.22 – 12.04″ WC) depending on plate distances and model

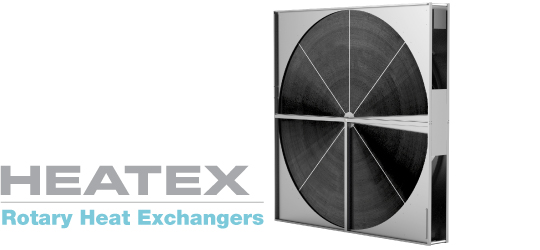

Heatex Model E & EQ

Heatex rotary heat exchangers enable humidity transfer and generally provide higher efficiency than a plate heat exchanger.

Typical options for dehumidification applications include:

- Epoxy-coated matrix

- Corrosion protected framework

- Power belt for high reliability, easy maintenance, and adjustment

- Various motor options. E.g., a constant motor for simplicity or a step drive motor with frequency control and Modbus for flexibility

Case Study

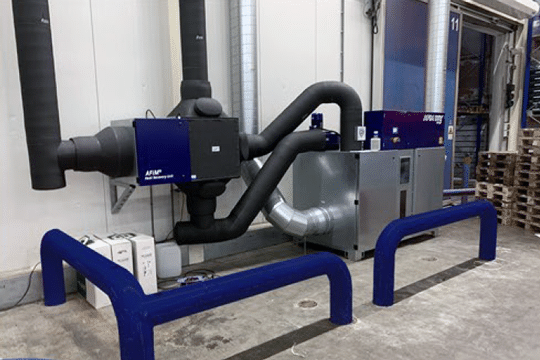

Air in Motion B.V. has developed solutions for managing the moisture load in cold stores and cold storage for many years, developing in-house customized solutions specific to their client’s needs for industrial air drying.

Read Case Study