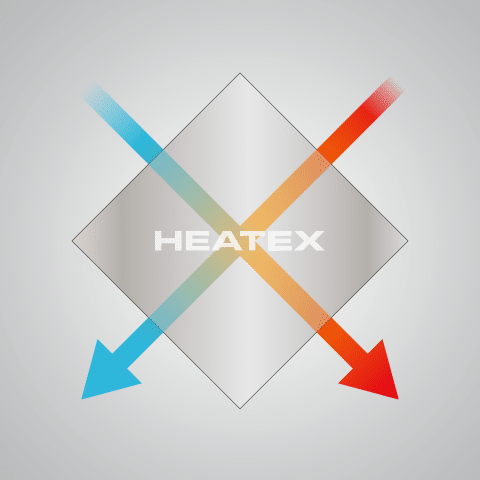

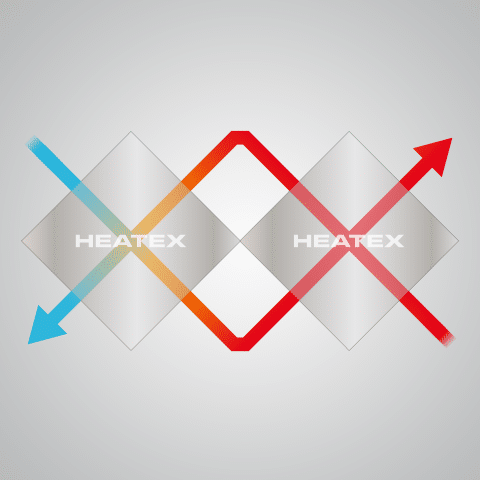

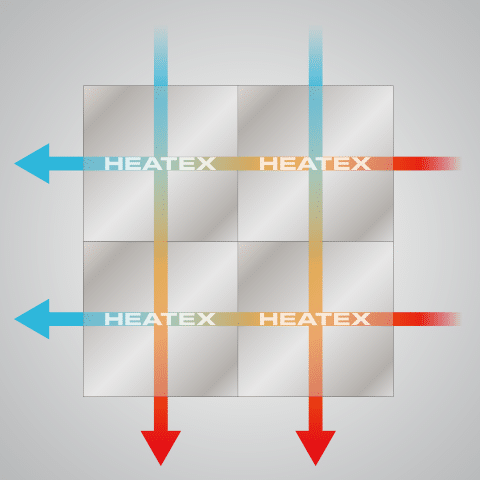

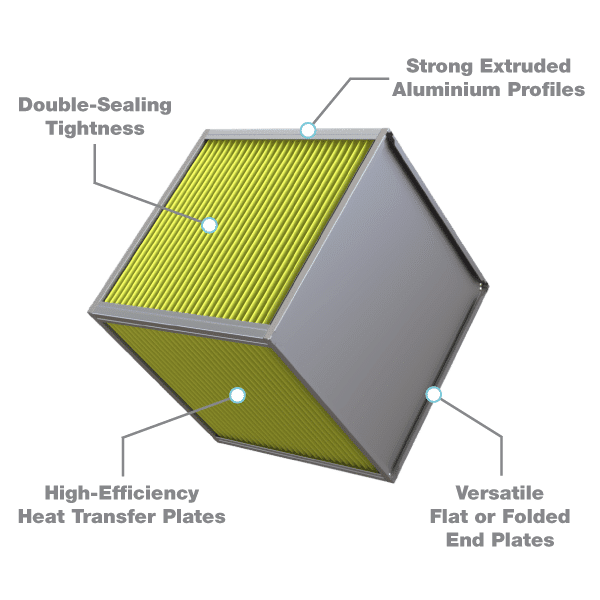

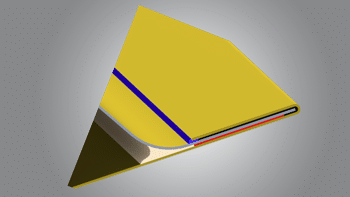

In a crossflow heat exchanger, the cold and the warm air flow perpendicular to each other. Two neighboring aluminum plates create channels for the air to pass through. The supply air passes on one side of the plate and the exhaust air on the other. The heat in the exhaust air is transferred through the plate from the warmer air to the colder air.

A very important parameter for the performance of a plate heat exchanger is the spacing between the plates. A narrow channel leads to high-pressure drop but also to high efficiency. The latter means that more heat is transferred to the cold side. A higher plate distance is better if a lower pressure drop is required. The trade-off is lower efficiency.

Usually, the exhaust air is contaminated with humidity and pollutants, but with a plate heat exchanger, airflows never mix, leaving the supply air fresh and clean.