Indirect Dry or Evaporative Cooling

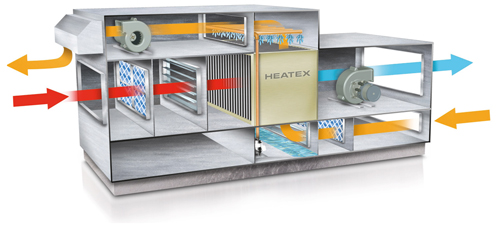

Cooling is a key factor in the cost and operation of data centers. Air-to-air heat exchangers are used for indirect dry and evaporative cooling solutions to remove excess heat from the data center air in a closed-loop system.

Indirect Cooling in Data Centers

Modern data centers are remarkably technologically complex, and keeping them running safely and efficiently requires continual close monitoring and management.

Maintaining the correct temperature is among the most important tasks faced by data center managers. Should the temperature and humidity rise to excessive levels inside the data center, condensation can start forming, damaging the machines within. This can cause massive damage and disruption, so it must be avoided at all costs. Fortunately, various technologies are on hand that can help keep data center temperatures at the right level.

There are numerous ways to cool a data center. Indirect air cooling uses external air, but by including an air-to-air heat exchanger, the outside air is kept in a separate loop, providing cooling without entering the server room.

Indirect cooling methods benefit by not contaminating the inside air with outdoor air pollutants and humidity. A heat exchanger keeps both airstreams separated while transferring the heat from the inside to the outside of the data center building. Consequently, the ambient and indoor air never mix.

Dry cooling is usually sufficient if the data center is located in a consistently low-temperature area, meaning no water is involved. However, by spraying water on the ambient air side of the heat exchanger, an evaporative effect is achieved, resulting in a lower indoor air temperature. This method is called indirect evaporative cooling (IEC).

Ideally suited for warm, dry climates, IEC provides excellent cooling potential with low operational- and first-cost. Ambient temperature reductions of 6-8 °C (10-15 °F) are typical in summer conditions. IEC provides up to 28% in energy savings compared to conventional free cooling and 52% to air-cooled Free Cooling alternatives.

Evaporative cooling requires a plate heat exchanger that balances high efficiency with low pressure drop, offers solid corrosion protection, and reliable water tightness. Heatex cross-flow heat exchangers meet all these requirements while providing outstanding cooling capacity.

Our crossflow heat exchangers, especially with evaporative cooling technology, provide an efficient, low-cost, and environmentally friendly alternative to traditional cooling methods.

Using our product selection software, Heatex Select enables accurate calculations of our products’ performance under different conditions.

IEC Optimized Cross Flow Heat Exchangers

Maximum Energy Efficiency

Achieve the perfect balance of energy efficiency and pressure drop by choosing between two unique plate patterns and numerous plate distances. All plates are made of high-grade aluminum plates with turbulence-enhancing patterns.

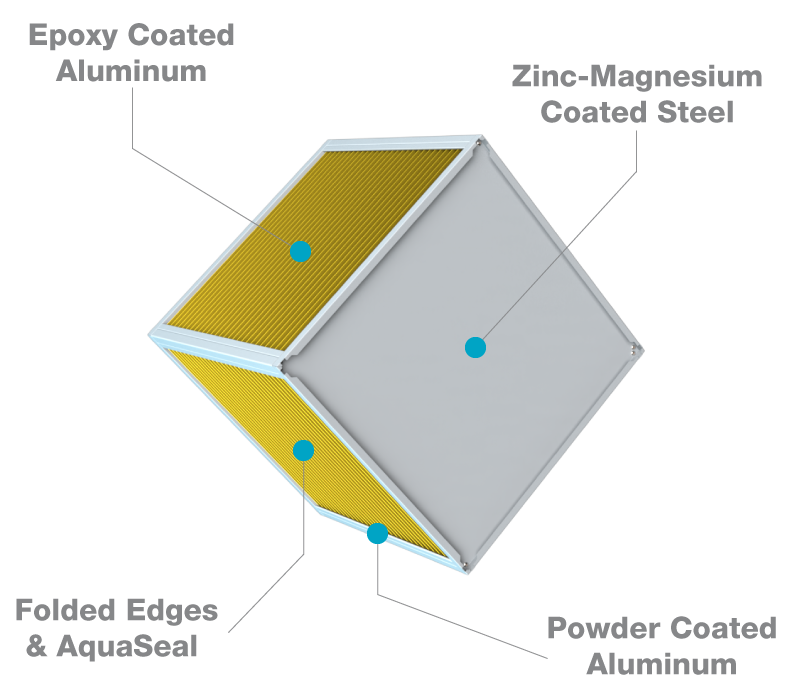

Corrosion Protection & Water Tightness

Single or multilayered epoxy-coated plates, zinc-magnesium-coated steel end plates, aluminum profiles, and lacquered plate edges assure complete corrosion protection for the expected product lifetime (>15 years). Folded edges with AquaSeal sealings together with rigorous testing secure water tightness.

Cost-Effectiveness

Lower operating costs than refrigerant-based cooling methods.

Local production in Europe and China promotes on-time delivery and cost control.

Recommended Products for Data Center Cooling

The Most Versatile

Model H is Heatex’s original cross-flow plate heat exchanger. It comes with either a single or multilayer epoxy for upgraded corrosion resistance. Extra high plate distances minimize pressure drop.

Heatex Crossflow Heat Exchangers

The Most Efficient

Model H2 is our most efficient cross-flow plate heat exchanger. It combines low weight with high differential pressure resistance and either a single or multilayer epoxy for upgraded corrosion resistance.

Heatex Crossflow Heat Exchangers| Application | Indirect Dry Cooling | Indirect Evaporative Cooling | |||||

| Does it need to be watertight? | No | Yes* | |||||

| Recommended material | Aluminium | Epoxy | |||||

| Coating options | None | Single | Multilayer** | ||||

| Suitable models | H | H2 | H | H2 | H | H2 | |

*To make sure the exchanger is completely watertight, testing is required.

**Local differences between our production sites might occur.

Ask an Expert

Heatex is a global leader in data center cooling applications, both dry and evaporative cooling, and we work with several of the leading players in the industry in all geographic regions.

Our skilled and experienced application engineers support our customers during the entire development process.

Contact Us

Proven Technology

Thousands of Heatex plate heat exchangers are operating in data centers all over the world.

Solid Track Record

Over 10 years of experience supplying top-of-the-line plate heat exchangers for data center cooling.

Extensive Capabilities

With production facilities in Europe and China we are always close and accessible.