Why Heat and Energy Recovery?

By recovering heat, energy consumption is reduced. Saved energy cut costs and the consumption of coal, natural gas, and other fossil fuels, eventually reducing carbon dioxide.

Return on Investment

The ventilation of buildings significantly adds to the total amount of heat loss. However, constant air exchange is required to introduce fresh air to maintain a comfortable and healthy indoor climate. The heat loss can be reduced when the heat from the exhaust air is transferred to the supply air.

Whereas the savings in commercial and residential ventilation applications might be easier to grasp, industrial ventilation applications also offer many ways to profit from otherwise wasted heat. Consequently, a heat exchanger is almost always a beneficial investment – regardless of whether the exchanger is a rotary or a plate heat exchanger.

All our models save sufficient energy to provide short amortization periods and valuable savings.

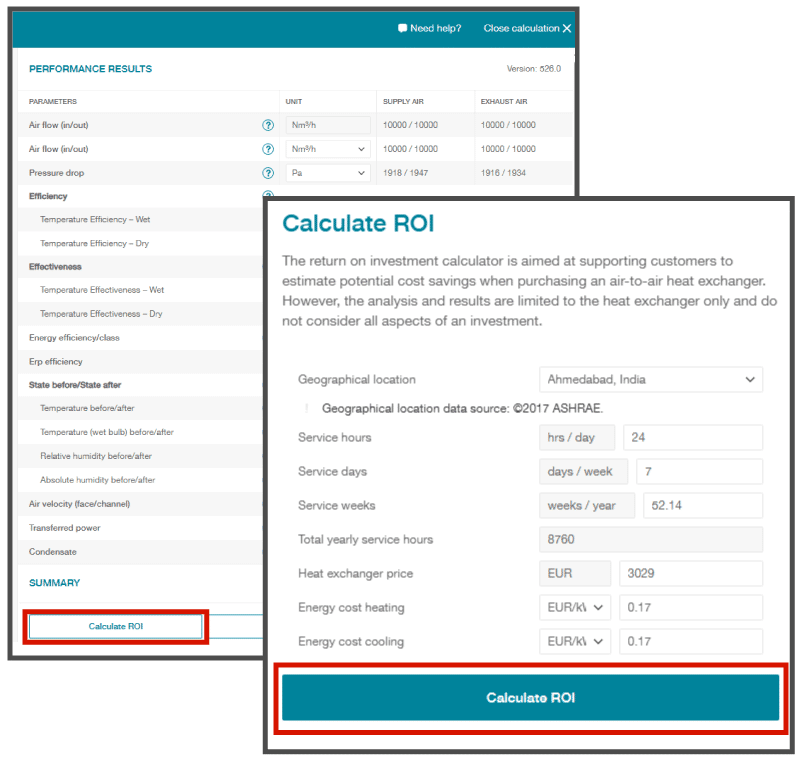

In Heatex Select Online, you will find a Return on Investment Calculator that approximately indicates the payback amount, time, and energy saved by installing a Heatex air-to-air heat exchanger. It features rotary and plate heat exchangers and is under the “Summary” tab at the end of the calculation process. Below, you’ll find a brief tutorial on calculating the return on investment of a Heatex air-to-air heat exchanger in Heatex Select Online. This Calculator is exclusively available in Heatex Select Online.

Calculate Return On Investment

In Heatex Select Online, the return on investment calculator becomes available once you have calculated the performance results for a specific product.

Follow the steps below to calculate the ROI for a rotary or plate heat exchanger.

- Go to Heatex Select Online

- Select Rotary or Plate Heat Exchangers

- Enter your Air Data and Product Configuration

- Click Calculate

- Click Calculate ROI

- Enter the Geographical Location

- Change any data necessary

- Click Calculate ROI

- Click Include in PDF (optional)

- Click Export PDF (optional)

The Results

Key results are the Total yearly energy reduction, Yearly Savings, and the Payback Period.

You will also find an estimation of CO2 emission reduction based on the energy saved by the heat exchanger.

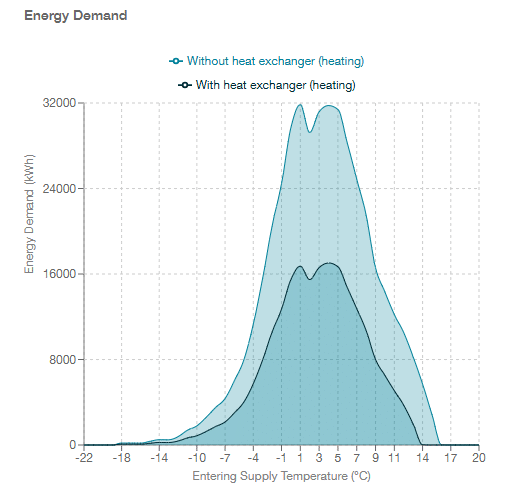

Under Installed Heating/ Cooling Power, we compare the required heating and cooling coil capacity. Under Energy Usage, we compare annual energy demand with and without an air-to-air heat exchanger.

The corresponding graphs support the numbers visually and make it easier to grasp the results.

Note that the heat exchanger price is required to calculate payback time. Otherwise, the result is limited to energy savings only.

Heat exchanger price also can be considered the total cost investment, thus, payback is calculated for the entire system.

Carbon Dioxide Reduction

The combustion of fossil fuels contributes to the increasing amount of CO2 in the atmosphere. Higher concentrations of CO2 in the atmosphere add to the greenhouse effect and increase the average temperature on Earth.

The higher average temperature on Earth will eventually melt the polar ice caps, increase the ocean level, cause climate change, etc.

Heatex contribution to the reduction of CO2 by crossflow and rotary heat exchangers totals approx. 7.000.000 tons CO2 / year.

This is equivalent to the pollution from 2.500.000 Cars!

Total CO2 reduction by the installed base of Heatex rotary heat exchangers:

| Saved energy per year per RHE* | Approx. 250 000 kWh/ year |

| Months per year in operation | 6 months/ year |

| Estimated lifetime | 10 years |

| Recovered heat power (ErP 73%) | Approx. 57 kW |

| EU member states (28) average of CO2 equivalent pollution from electricity consumption | Approx. 300 g CO2/ kWh |

| CO2 – reduction/year/RHE | Approx. 73 000 kg/ year/ RHE |

| Total CO2 -reduction | Approx. 2 000 000 metric tons CO2/ year |

* Model E, wheel diameter: 1500 mm, well height: 2 mm, width: 200 mm.

Total CO2 reduction by the installed base of Heatex plate heat exchangers:

| Saved energy per year per PHE* | Approx. 82 000 kWh/ year |

| Months per year in operation | 6 months/ year |

| Estimated lifetime | 10 years |

| Recovered heat power (ErP 73%) | Approx. 19 kW |

| EU member states (28) average of CO2 equivalent pollution from electricity consumption |

Approx. 300 g CO2/ kWh |

| CO2 – reduction/year/PHE | Approx. 24 000 kg/ year/ PHE |

| Total CO2 – reduction | Approx. 5 000 000 metric tons CO2/ year |

* Model H2, plate size: 750 mm, well height: 2,1 mm, width: 718 mm.