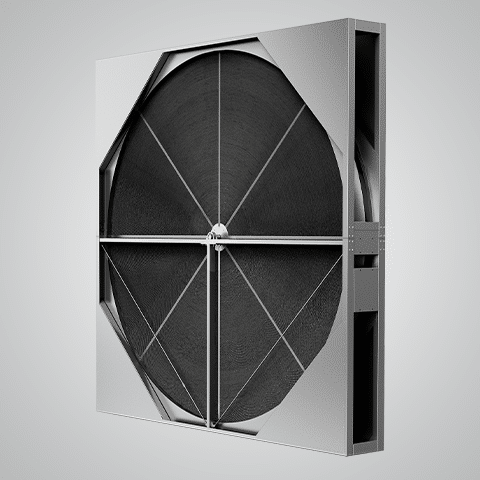

Rotary heat exchangers are often referred to by different names depending on their design, function, or industry context. Here’s a breakdown of the most common terms and how they relate to each other.

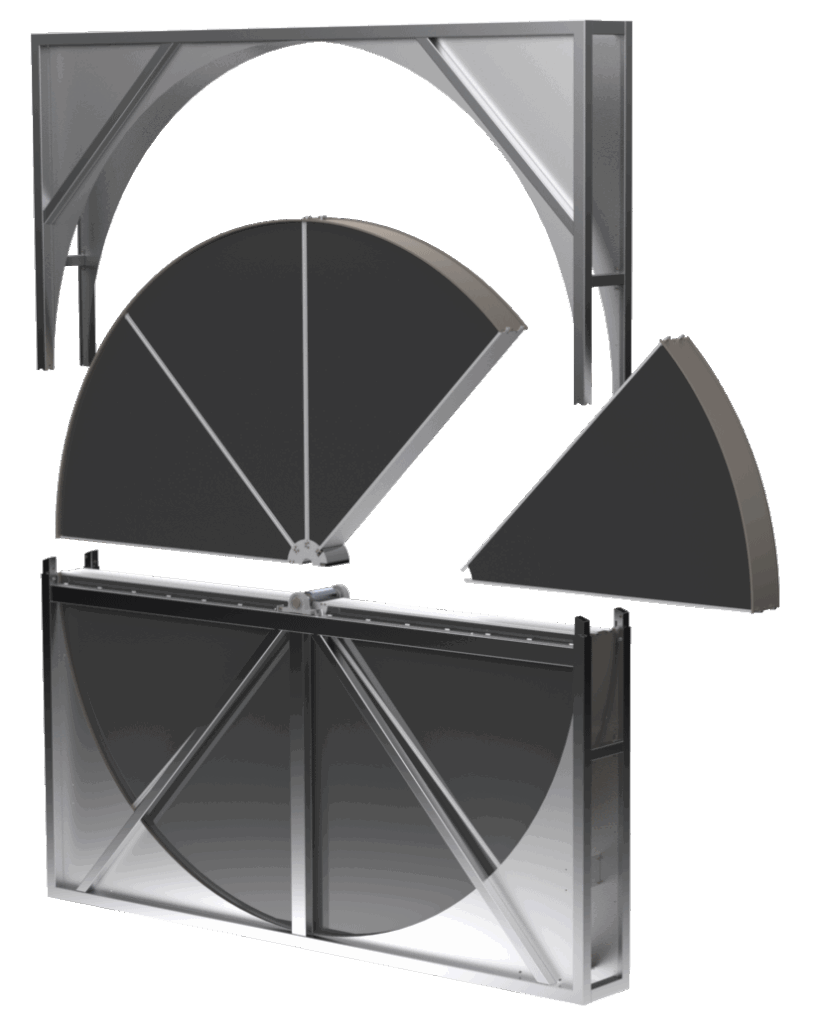

The Air-to-Air Rotary Heat Exchanger and the Air-to-Air Rotor

Both describe systems that transfer heat between two airflows—typically the exhaust and intake air in a ventilation system. These terms emphasize the application of the technology, which involves recovering heat from outgoing air and using it to precondition incoming air, thereby improving energy efficiency.

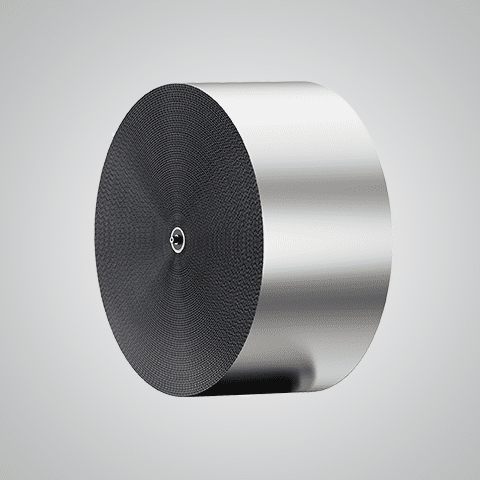

Rotary Heat Exchangers and Rotating Heat Exchangers

Are general terms that refer to any heat exchanger that uses a rotating wheel to transfer heat. These devices can handle sensible heat (temperature) and, in some cases, latent heat (moisture), depending on the material and design of the wheel. These terms are often used interchangeably in technical and commercial contexts.

Thermal Wheel

Is another name for a rotary heat exchanger, typically used when referring to systems that transfer only sensible heat. This term is commonly used in building ventilation and data center cooling, where moisture transfer is not typically required.

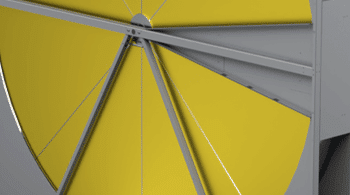

Enthalpy Wheel

Refers to a specific type of rotary heat exchanger that transfers both sensible and latent heat. These wheels are coated with hygroscopic materials that allow them to absorb and release moisture, making them ideal for applications where humidity control is essential, such as in humid climates or tightly sealed buildings.

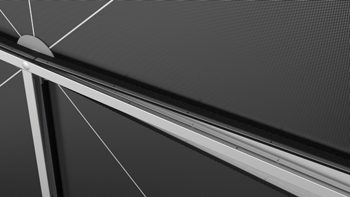

Adsorption Rotor

Is a more specialized term used for systems that focus on moisture removal through adsorption. These rotors are typically used in industrial drying, pharmaceutical environments, and clean rooms. They utilize materials such as silica gel or molecular sieves to capture moisture from the air, providing high-efficiency dehumidification.

While these terms may seem different, they all refer to variations of the same core technology: a rotating component that facilitates heat and, in some cases, moisture transfer between air streams. The differences lie in the specific function, material, and application of the exchanger.